+48 51 05 07 566

Sales support

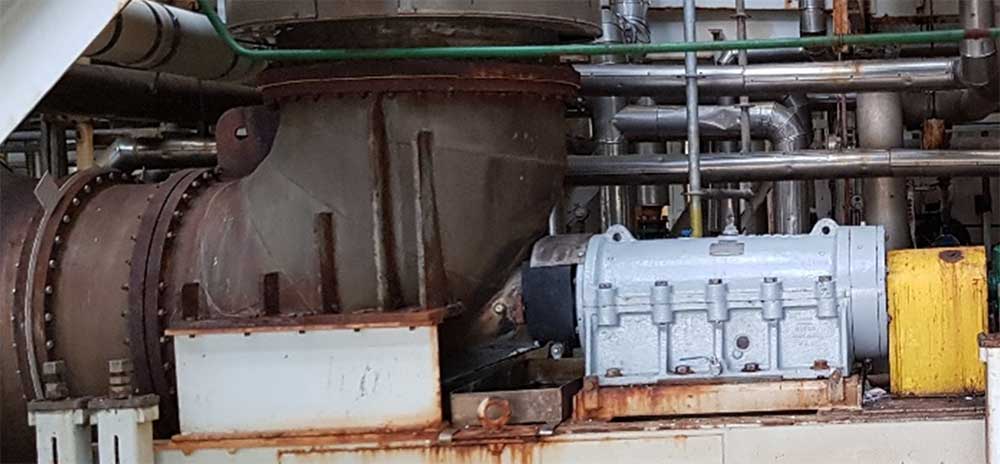

Refit description

After the gear was disassembled into parts, raids were found on the inner races of the bearings, which were caused by high operating temperature of the gear.

The condition of the teeth on the attacking shaft shows the first signs of damage.

The condition of the teeth of the large toothed wheel does not show any signs of wear. The tooth profile remains intact.

The condition of the pump shaft is good. A detailed report on shaft measurements will be presented in the appendix. Bearings mounted on the shaft show the first signs of peeling of the outer race. Bearing clearance on the rotor side is normal (0.15 mm), bearing clearance on the gear side is normal (0.18 mm).