+48 51 05 07 566

Sales support

Refit description

Cover of the MP2 pump before refit.

Cover of the MP2 pump before refit.

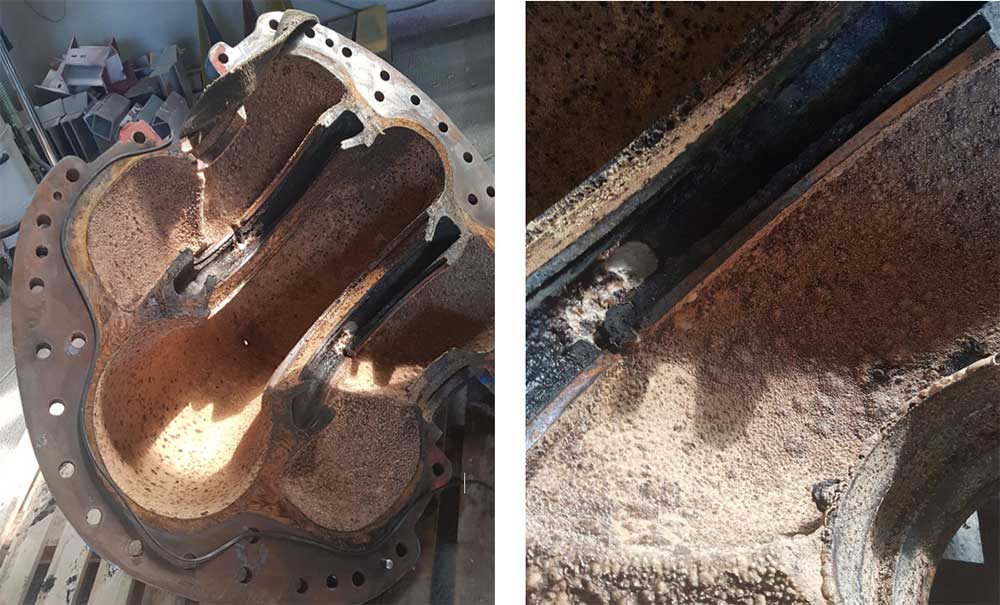

The photos above show the build-up of residue on the MP2 pump body. The residue was created as a result of a chemical reaction of the cast iron body with the pumped pulp. The reaction caused local defects on the inner surface of the pump. The cavities in the body were up to 5 mm deep.

The above photos show a residue formed on the cover of the MP2 pump. As in the case of the lower pump body, the residue was created as a result of a chemical reaction of the cast iron body with the pumped pulp. The reaction caused local defects on the inner surface of the pump. The cavities in the cover were up to 5 mm deep. Due to the fact that the pump is only 4 years old, the losses are very large. The applied ceramic coating should permanently protect the pump housing against similar effects for at least 5 years.

The photo shows the lower body of the MP2 pump after application of the first layer of CF ceramics. During the application of the first layer of ceramics, the defects in the body caused by the erosive action of the paper pulp were filled up.

The photo shows the cover of the MP2 pump after the first layer of CF ceramics has been applied. During the application of the first layer of ceramics, the defects in the body caused by the erosive action of the paper pulp were filled up.

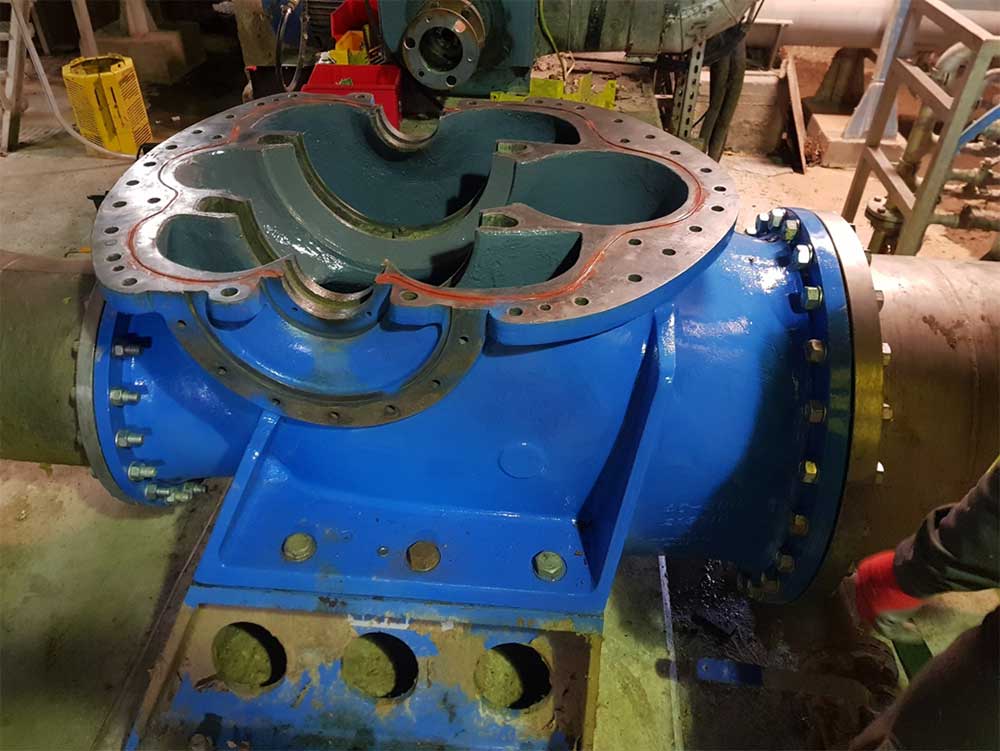

The photo above shows the lower body of the MP2 pump mounted to the installation. The body has been covered with a second layer of ceramics, the adhesives have been sanded, the o-ring has been glued, and the body has been repainted with original varnish from the outside.

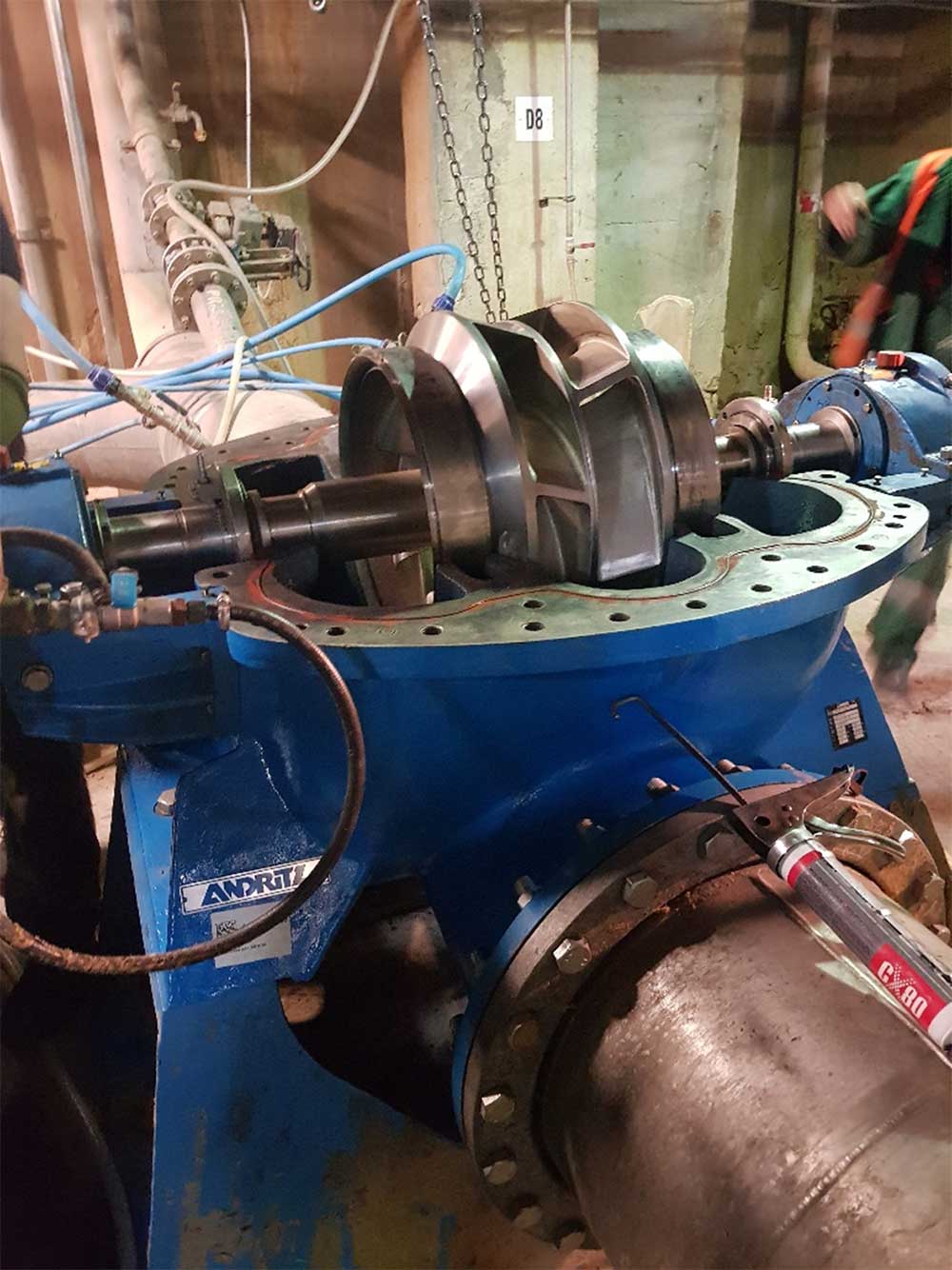

The photo above shows the lower body of the MP2 pump with the rotating assembly installed and armed. The rotating assembly was mounted and armed by the PMP Rolls company.